In the dynamic world of e-commerce, ensuring product quality is a top priority for both buyers and sellers. Sugargoo, a leading shopping and shipping agent, has established an exceptional Quality Control (QC) process to guarantee that every item meets high standards before reaching customers. Their systematic approach involves documenting detailed inspection records in a structured spreadsheet, creating a robust QC framework.

The Structure of Sugargoo’s QC Spreadsheet System

Sugargoo’s QC team meticulously documents multiple aspects of product inspections in an organized spreadsheet template. Each item undergoes thorough checks for:

- Material Quality:

- Workmanship:

- Accuracy:

- Packaging:

- Visual Defects:

- Workmanship:

These findings are systematically logged in pre-defined spreadsheet columns alongside timestamps, inspector notes, and photographic proof where applicable.

Why the Spreadsheet System Benefits Customers

Transparency is key in Sugargoo’s QC spreadsheet approach:

- Avoid Suspicious Items:

- Inspection Efficiency:

- Accountability:

- AI-Assisted Data Analysis:

- Inspection Efficiency:

Accessing Your Product’s QC Report

On Sugargoo’s platform, integrated QC reports generate upon inspection completion. Customers review these documents anytime via:

- The order tracking page with summarized grades (e.g., “Grade A” for near-perfect items).

- Expanded spreadsheets within the account portal showing raw QC remarks.

- Optional email attachments containing timestamped inspection snapshots.

Filling Transparency Gaps in E-Commerce

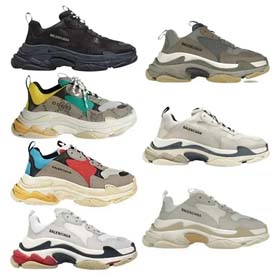

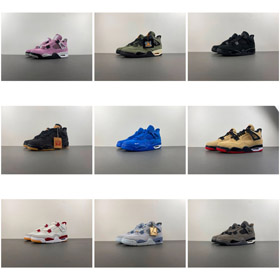

Unlike ambiguous product listings, Sugargoo quantifies quality through structured data recording. This system identifies repeat sellers with poor craftsmanship (based on historical spreadsheet flags) while verifying trustworthy vendors – an approach particularly valuable for sneaker authenticationluxury batch comparisons.

Netizens shopping via agents appreciate Sugargoo’s spreadsheet-backed reports, stating: “The flaw diagram showed EXACTLY where the logo print was smudged – zero guesswork.”